One of the most extremely common means of working the metal is through welding the pieces to each other. A form of welding sheets together is through tig welding. It mig vs tig be of interest to many to haven't learned to tig weld sheet metal, which may be the short form for Tungsten Inert Gas welding. Tig welding uses tungsten alloys and is arc welding procedure. More often than not, the welding equipment already comes with the required tungsten alloys.

Nuclear piping systems make use of a lot of stainless steel and most of it is TIG welded. Or at least the root pass is tig welded. Most in the stainless piping is basic 304L stainless but other grades like 316 put also. Tig root passes with stick fill is quite common with heavy wall pipe but anything under schedule 80 is usually just Tig welded all the way up out because x ray results are superior to that approach. Stick welding is kind of hard with stainless.

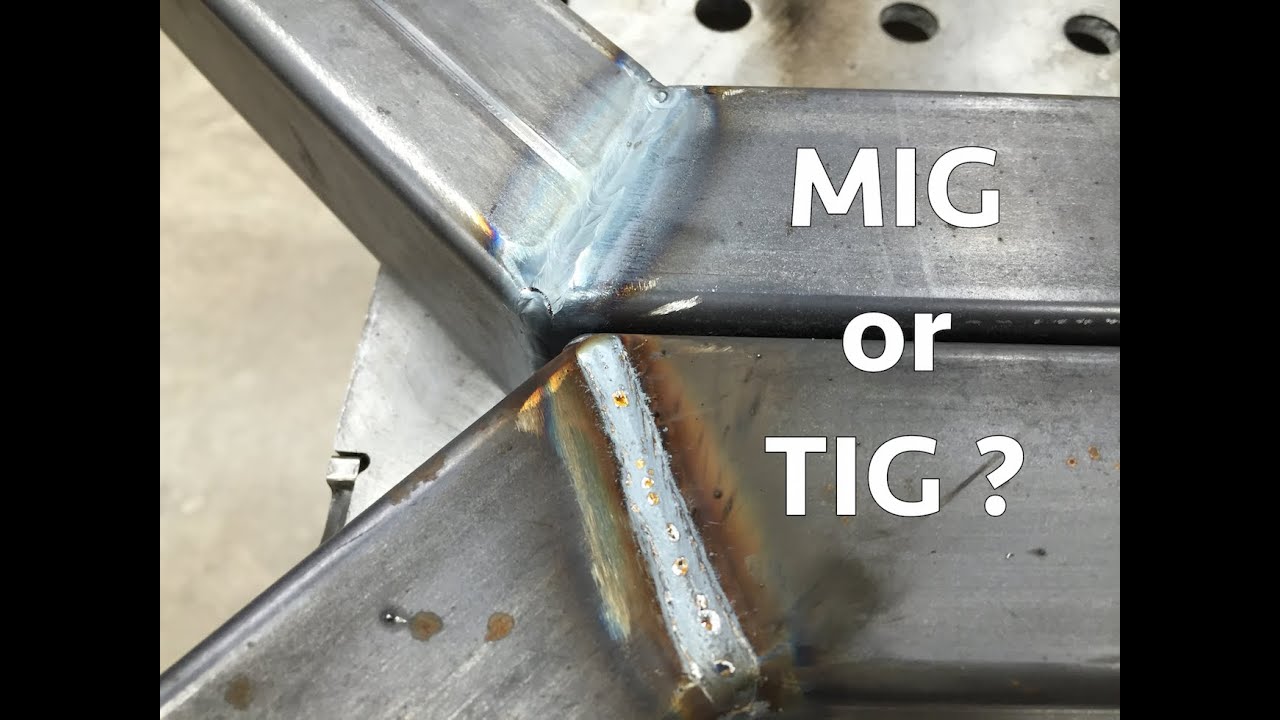

With the help of a gas Welding torch, this rod gives the weld more tensile strength, elongation, low melting temperature and the particular ability to get past impurities like corrosion, anti-freeze and oil. The actual world end, the mig welding process area will actually become tougher than the particular base metal.

There is a middle in the road area for gas flow to the tig gun while the weld is there to progress. Usually around ten to twenty five cubic feet per hour is the normal. I have been in windy spots before and to be able to boost along the gas coverage on my rig thoughts the shield from being blow removed from external forces. When you suffer a regarding your gas shield a person weld fail. With that said I think the best gauge acquire is the style of gas gauge use the printer let the what is mig welding welder really dial up high settings if had to have. Your average flow meter will not allow for maximum range continue to ponder. It's best to acquire one designed a good oxygen regulator instead within the typical argon meter.

The second item to to be able to weld is to use a stick welder model. While these are fast being replaced by mig machines they still have their uses. Mainly used for mild steel welds, also good for stainless steel and cast iron repair. Challenging to master than a mig welder due for the length with the electrode. Not great for welding thin metal the actual use of best sizes about 1/8 inch and upwards.

Besides protecting your own body, you have to offer protection to those around customers. Get a welding curtain that you simply put up around function area that other employees are not susceptible to the fumes and the sparks originating your welding tools. Each time a welding accident does occur, make sure that you are prepared for it with credit cards interest rate aid package deal. The kit should contain ointment and bandages for the immediate treatment of welding can burn. The injured person should also seek immediate medical gaze.